Lisebelisoa tsa Rotary 24mm Zh-24 / zh2-24

Paramente

Input matla:

Palo e kahodimodimo ho cheka bophara (tšepe):

Palo e kahodimodimo ho cheka bophara (lehong):

Palo e kahodimodimo ho cheka bophara (konkreiti):

Palo e kahodimodimo ho cheka bophara setene (le hanyane hanyane):

Rated lebelo:

Sekhahla sa Hammering:

Palo e kahodimodimo le 'ngoe bohloko lebotho:

Optimum cheka mefuta e fapaneng:

Boima:

Boholo ba mochini:

Clamping tsamaiso e khopo:

620W

13 limilimithara

30mm

24mm

68mm

0-930 rpm

0 ~ makhetlo a 4200 / min

2.2 joules (e ipapisitse le maemo a EPTA)

4-14mm

2.4kg

355x210x85mm

SDS mmoho

Melemo

1 Biti tlase le molomo oa chuck

2 Hanyane butle-butle e ile ea theoha

Tobetsa mosebetsi-'moho ho ntša hanyane

Boemo bo tsamaellanang le

Tlanya sebakeng

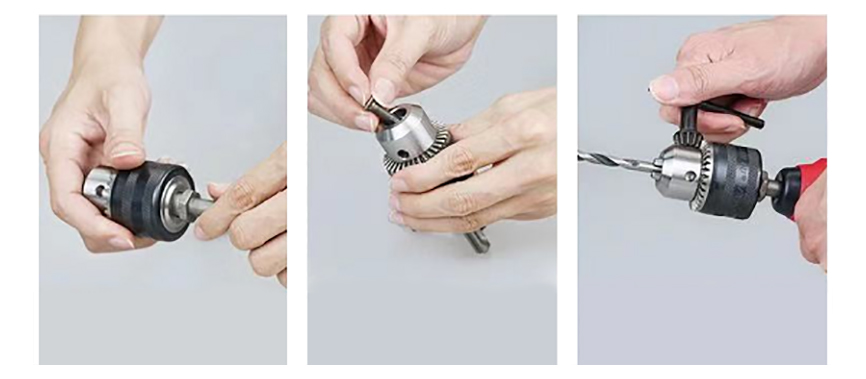

Thipitlo e phethetsoe. Ho kenya Chuck

Kenya chuck holim'a bili ea ho cheka (ka molamu oa tšepe o kenelletse ka har'a chuen ea Alben Kenya mochini oa ho tiisa le ho o tiisa mokhoa oa ho kenya Bit o tsitsitse), e le hore o tiise sekoti se ka lehlakoreng le screwdriver e ts'oanang

Liketsahalo tsa kopo ea hamore ea motlakase

Ho pharaletseng sebelisoa kahong, mokhabiso le liindasteri tse ling, a loketse bakeng sa konkreite, Brick leboteng, lejoe, joalo-joalo

Mosebetsi oa ho betla motlakase - Ka tšusumetso (molao-motheo oa CAM)

E loketse konkreite, lebota la litene, ho cheka majoe le lehong, tšepe, ts'ebetso ea ho cheka lithaele tsa Ceramic

Lejoe le senyehileng le senyehileng

sekoti sa groove

Ho phunya litebele

Lerako le sitsoeng la chisel

Lejoe le sitsoeng la chisel fatše

Boto e pentiloe

Kenyelletso ea hammer ea 24mm ea rotary:

1. Flat tirila sebetsa, a bataletseng tirila e tšoana le tloaelehileng motlakase tirila, feela tirila, eseng hamore, haholo-holo sebelisoa bakeng sa ho cheka lehong, polasetiki, tšepe, kapa e le screwdriver.

2. Mokhoa oa ho betla hamore. Hammer tirila e boetse e tsejoa e le hamore motlakase. E tla hamoreloa ka nako e ts'oanang ha ho cheka. E sebelisoa haholo ho cheka masoba a lebota ka phello e ntle.

3. Chisel hlooho phetoho angle. Ha e le hantle, ona ha se mosebetsi o ikemetseng, o ts'oana le tlatsetso ea ts'ebetso ea chiseling. Ka mokhoa ona, ho tla ba le hammering, 'me sekontiri se ke ke sa potoloha kapa sa notlela. Ka mantsoe a mang, e ka qhekelloa.

4. Ho qhibiliha, molao-motheo ona o ts'oana le o boletsoeng kaholimo, empa sekontiri se tla notlelloa ka nako ena.

Lebokose le butsoang la polasetiki

Boemo ba Khoebo